In the world of construction and interior design, U Light Steel Keels play a crucial role in the structural framework of drywall systems. These steel keels are essential components in creating durable, cost-effective, and lightweight support for ceilings, walls, and partitions. At the heart of the production of these keels is the U Light Steel Keel Roll Forming Machine, an advanced piece of machinery designed to efficiently produce these essential profiles.

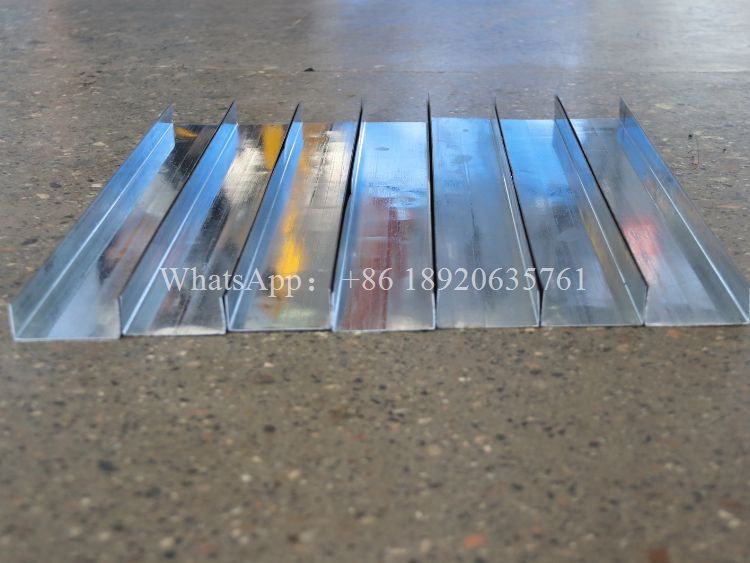

A U Light Steel Keel Roll Forming Machine is a specialized type of profile roll forming machine. It uses continuous steel coils to form a variety of profiles, specifically the U-shaped steel keel profiles that are commonly used in drywall systems. The process involves feeding steel coils into the machine, which then forms them into precise U-shaped profiles, often referred to as keels. These keels are critical for supporting gypsum board or plasterboard, providing a stable structure for interior walls and ceilings.

The keel machine is engineered to handle high-speed production while ensuring consistent quality in the profile forming process. It allows manufacturers to produce these keels in large quantities, making it a cost-efficient solution for the building industry.

1.High Efficiency: The keel manufacturing machine is designed for high-speed operation, ensuring that the profiles are produced quickly without compromising on quality.

2.Customization: With adjustable settings, the profile making machine can produce a wide range of U-shaped profiles, meeting different thickness and size requirements for various construction applications.

3.Durability: The keel making machine is built with robust materials, ensuring long-term reliability and minimal maintenance costs.

4.Automatic Control: Modern profile forming machines come with PLC control systems, allowing for automated operation, reducing labor costs, and increasing the overall efficiency of production lines.

The U-shaped steel keels produced by keel machines are widely used in the construction of lightweight drywall systems. These systems are typically found in:

1.Office Buildings: For partitioning office spaces and creating ceiling grids.

2.Residential Buildings: Used in creating internal walls, ceilings, and partition systems.

3.Commercial Spaces: For creating modular and reconfigurable interiors in shops, malls, and other commercial environments.

4.Industrial Facilities: Lightweight partitioning and ceiling support for warehouses and factories.

These keels are not only lightweight but also highly durable and resistant to fire, making them a perfect choice for modern construction projects that require flexibility, safety, and sustainability.

When considering the production of U-shaped steel profiles, it's essential to choose a drywall making machine or U channel roll forming machine that can deliver high-quality results consistently. The track roll forming machine (another term for a keel machine) used in the production of steel keels ensures precision and accuracy, meeting the exact specifications needed for drywall and ceiling systems.

Additionally, U channel forming machines are designed to work with a variety of materials, not just steel, which allows for the production of different profiles, including C-channels and other forms of structural support.

The U Light Steel Keel Roll Forming Machine is a cornerstone of modern construction and interior design. Its ability to produce precise, high-quality U-shaped steel profiles quickly and efficiently makes it an essential tool for keel making machine manufacturers. Whether you are working on a large-scale commercial project or a residential build, investing in a high-performance profile roll forming machine can greatly enhance the quality and speed of your operations.

At PROMAX GROUP, we specialize in providing advanced keel machines and profile forming machines that cater to the specific needs of the construction industry. Our machines are designed for reliability, precision, and efficiency, ensuring your business can meet the demands of modern construction projects with ease.