WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

Featuring high automation;

Superior precision;

Excellent efficiency;

User-friendly operation.

WhatsApp: 0086 18920635761

E-mail: lisa@hx-machinery.com

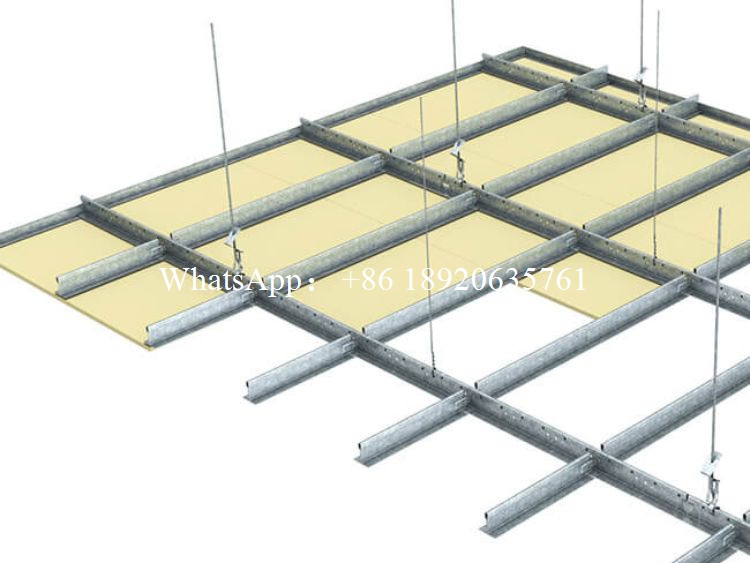

In the world of modern construction and interior fit-outs, efficiency and precision in manufacturing building materials are paramount. For businesses specializing in ceiling systems, investing in a high-performance T Grid Ceiling Channel Roll Forming Machine is a strategic move toward enhanced productivity and superior product quality. This sophisticated equipment seamlessly transforms metal coils into precise T-grid channels through a fully automated, continuous process.

The operational excellence of the T Grid Ceiling Channel Roll Forming Machine is built upon a seamlessly coordinated sequence of specialized stations.

The core operation begins with decoiling, where the metal strip is fed into the system.

It then proceeds through a series of precision-rolling stations that gradually cold-form the metal into the required T-shaped profile.

This is followed by integrated punching for accurate hole patterns and a flying cut-off system for clean, length-specific cropping.

The finished channels are then automatically stacked or conveyed, ensuring a smooth workflow with minimal manual intervention.

| Product Name | T Grid Ceiling Channel Roll Forming Machine Price |

| Formed Material | Galvanized steel strip |

| Machine size | 5900*900*1500 mm |

| Machine weight | 2400 kg |

| Thickness | 0.45-0.9 mm |

| Decoiler |

Vertical manual decoiler (load capacity 1.5 tons) (will give you as free) |

| Roller station |

18 rows(As your requirement) CR12 heat treatment 58-60 ℃

|

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | SKD11 heat treatment at 58 degrees Celsius |

| Power | 15+5.5KW |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase(customizable) |

| Forming speed | 40 m/min (The speed depends on the shape of the tile and the thickness of the material) |

| Transmission method | Gear transmission |

| Cutting tolerance | +-1.0 mm |

Beyond automation, our machine stands out for its advanced features designed for the global market. Customization is a cornerstone, with flexible options for material entry width, roll forming thickness, operating voltage, and multi-language touchscreen controls. Furthermore, we integrate smart connectivity, allowing engineers to provide remote quality assurance and real-time video guidance for maintenance or troubleshooting, reducing downtime and safeguarding your investment.

A critical aspect that influences the T Grid Ceiling Channel Roll Forming Machine price is compliance with international safety standards. Our machine proudly carries the CE certification, guaranteeing it meets the stringent health, safety, and environmental protection requirements for the European Economic Area. This certification not only facilitates smoother market access but also assures buyers of the machine's built-in safety and reliability, adding intrinsic value to the purchase.

Ultimately, the T Grid Ceiling Channel Roll Forming Machine price reflects a comprehensive package of advanced engineering, automated efficiency, future-proof customization, and certified safety. By choosing a robust and adaptable machine, you are not just buying a piece of equipment; you are acquiring a reliable production partner that will drive the quality and efficiency of your ceiling channel manufacturing for years to come. For a detailed quotation tailored to your configuration, please contact our engineering team. Contact us...→

28 years of professional R&D team

One-stop-solution for roll forming machine

Long-life stable running

High-precision finished products

High-quality raw materials

Brand electrical parts

About us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a T Grid Ceiling Channel Roll Forming Machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the T Grid Ceiling Channel Roll Forming Machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.