WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

Featuring high automation;

Superior precision;

Excellent efficiency;

User-friendly operation.

WhatsApp: 0086 18920635761

E-mail: lisa@hx-machinery.com

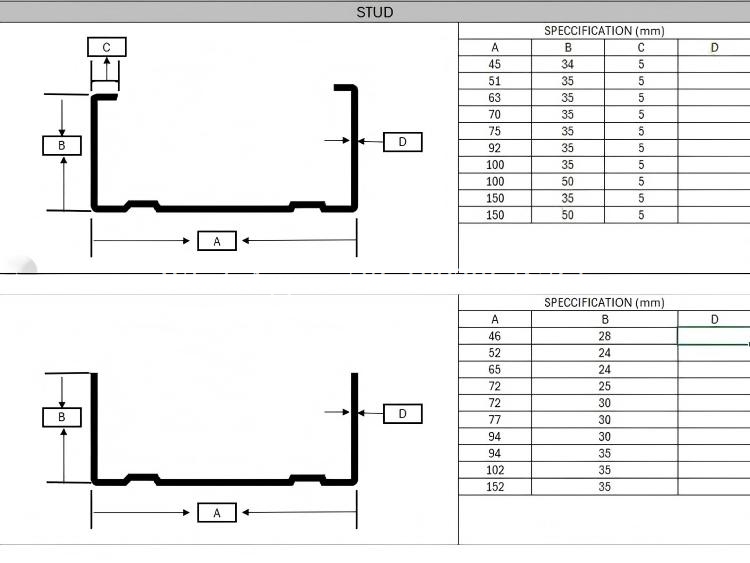

The global construction industry demands agile and efficient manufacturing solutions to keep pace with modern building requirements. Light steel keel framing relies on two fundamental components: the C-shaped stud and the U-shaped track. For fabricators managing separate production lines for each profile, space constraints, capital costs, and operational inefficiencies pose significant challenges. We are proud to present a transformative solution with our Production line for C U metal stud and track roll forming machine for sale. This innovative, integrated production system is engineered to fabricate both essential profiles on a single, intelligent platform. The Metal Stud and Track Roll Forming Machine for Sale embodies a new standard in manufacturing flexibility, designed to eliminate production bottlenecks, optimize floor space, and dramatically increase your operational responsiveness and profitability.

The operational brilliance of this Production line for C U metal stud and track roll forming machine for sale lies in its streamlined, automated process and revolutionary quick-change capability.

The system begins with a precision decoiler feeding steel coil into the machine.

The material is then accurately formed through a robust, multi-stage roll forming station, shaped into high-tolerance profiles.

The defining innovation is the integrated quick-change mechanism, centered on a rotating shear head system. To switch production from studs to tracks, the operator can swiftly rotate or reposition the cutting tooling via a simplified process, minimizing changeover downtime from hours to minutes.

Following forming, a high-speed servo shear delivers precise cuts, and an automated stacking unit prepares the finished products for shipment. This smart design of the Metal Stud and Track Roll Forming Machine for Sale allows a single operator to manage the production of a complete framing system, maximizing asset utilization and labor efficiency.

| Product Name | Production line for C U metal stud and track roll forming machine for sale |

| Formed Material | Steel strip |

| Machine size | 5900*900*1500mm |

| Machine weight | 2400kg |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12 rows(As your requirement) |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5KW |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase(customizable) |

| Forming speed | 40-50m/min(The speed depends on the shape of the tile and the thickness of the material) |

| Transmission method | Gear transmission |

| Cutting tolerance | +-1.0 mm |

Choosing this Production line for C U metal stud and track roll forming machine for sale offers profound economic and strategic advantages. By consolidating two manufacturing functions into one footprint, you achieve substantial savings in factory space, initial capital investment, and ongoing maintenance. The rapid changeover capability allows for just-in-time production, reducing inventory costs and enabling you to respond instantly to specific project demands. Furthermore, this Metal Stud and Track Roll Forming Machine for Sale is built for global application. We offer extensive customization, allowing you to specify the material entry width, steel thickness capacity, operational voltage, and the language on the user-friendly touch-screen HMI to match your local standards. Crucially, this machine is CE certified, providing unquestionable assurance of its compliance with the highest European safety, health, and environmental protection directives. This certification safeguards your investment and facilitates market access worldwide.

To ensure you realize the full potential of this versatile asset, the Metal Stud and Track Roll Forming Machine for Sale is backed by our comprehensive remote support ecosystem. Our engineers provide real-time video guidance for installation, changeover procedure training, operational optimization, and preventative maintenance, ensuring maximum uptime and a swift return on investment.

28 years of professional R&D team

One-stop-solution for roll forming machine

Long-life stable running

High-precision finished products

High-quality raw materials

Brand electrical parts

About us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a Production line for C U metal stud and track roll forming machine for sale. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Production line for C U metal stud and track roll forming machine for sale can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.