WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

Featuring high automation;

Superior precision;

Excellent efficiency;

User-friendly operation.

WhatsApp: 0086 18920635761

E-mail: lisa@hx-machinery.com

In the competitive construction manufacturing sector, where project deadlines are stringent and product consistency is paramount, the efficiency of your production line directly influences profitability and market reputation. For fabricators of light-gauge steel framing, the ability to produce C-studs rapidly and without interruption is a critical operational goal. This demands machinery that excels not only in velocity but also in unwavering dependability. Our Reliable high-speed C Stud Roll Forming Machine is engineered to meet this dual challenge head-on. It represents a fusion of robust construction and optimized design, purpose-built to deliver exceptional throughput while ensuring continuous, stable operation. Investing in a Reliable high-speed C Stud Roll Forming Machine is a strategic commitment to enhancing your production capacity, minimizing costly downtime, and securing a reliable supply of high-quality framing components.

The process begins with a precision decoiler that feeds steel coil into the system with consistent accuracy, forming the foundation for a smooth production flow.

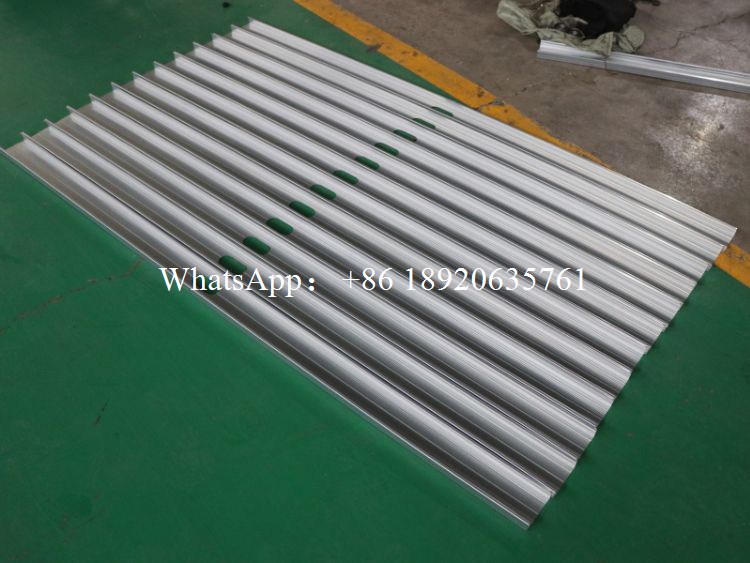

The material then advances into a heavy-duty, multi-station roll forming section. Here, through a series of hardened, precision-ground roller dies, the flat strip is progressively shaped into a perfect C-profile. The engineering focus on stability within this forming section is crucial to the machine's high-speed capability, ensuring profile accuracy is maintained even at peak operational rates.

Finally, a synchronized, high-speed flying cut system cleanly shears the formed stud to exact lengths.

| Product Name | Reliable high-speed C Stud Roll Forming Machine |

| Formed Material | Steel strip |

| Machine size | 5900*900*1500mm |

| Machine weight | 2400kg |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12 rows(As your requirement) |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5KW |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase(customizable) |

| Forming speed | 40-50m/min(The speed depends on the shape of the tile and the thickness of the material) |

| Transmission method | Gear transmission |

| Cutting tolerance | +-1.0 mm |

The Reliable high-speed C Stud Roll Forming Machine derives its reliability from superior engineering principles and high-quality components. The machine frame is constructed for rigidity and vibration dampening, which is essential for maintaining precision at high speeds. Critical drive and transmission systems are selected for durability and longevity, directly contributing to reduced maintenance needs and enhanced uptime. This inherent robustness ensures that the Reliable high-speed C Stud Roll Forming Machine can sustain its performance over long production runs, fulfilling the promise embedded in its name.

Furthermore, this machine is built for adaptability to meet diverse global manufacturing needs. It offers comprehensive customization to align with your specific operational parameters. Key aspects such as the material entry width, the forming thickness (gauge), the operational voltage, and the language on the intuitive touchscreen control interface can all be tailored. This flexibility ensures that the Reliable high-speed C Stud Roll Forming Machine integrates perfectly into your existing factory setup, allowing you to produce a wide range of C-stud specifications efficiently on a single, dependable platform.

28 years of professional R&D team

One-stop-solution for roll forming machine

Long-life stable running

High-precision finished products

High-quality raw materials

Brand electrical parts

About us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a Reliable high-speed C Stud Roll Forming Machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Reliable high-speed C Stud Roll Forming Machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.