WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

Featuring high automation;

Superior precision;

Excellent efficiency;

User-friendly operation.

WhatsApp: 0086 18920635761

E-mail: lisa@hx-machinery.com

The global construction industry is undergoing a transformative shift towards methods that are faster, stronger, and more sustainable. At the forefront of this revolution is light gauge steel (LGS) framing, the ideal solution for modern residential villas, commercial structures, and multi-story buildings. The efficiency and integrity of any LGS project depend entirely on the precision and quality of its core components. To empower manufacturers to lead in this high-growth market, we present our state-of-the-art Light Gauge Steel Frame Roll Forming Machine. This fully integrated, automated production line is engineered to fabricate the complete range of critical LGS profiles—including essential L-shaped angles for bracing and support—with exceptional accuracy and reliability.

Decoiler→ Leveling Device→ Punching Device→ Roll Forming System →Cutting Device →Out-let table

The production follows a meticulously automated workflow: It begins at the Decoiler, which feeds the steel coil into the line. The material is then perfectly flattened by the Leveling Device, eliminating any internal stress or curvature to ensure a flawless start. Next, the Punching Device creates precise, clean holes for utilities, services, and mechanical connections according to specific architectural plans. The heart of the system is the Roll Forming System, where the strip is progressively shaped through hardened tooling into the required structural profiles. The Cutting Device, typically a high-speed servo shear, then delivers accurate, burr-free cuts. Finally, finished components are neatly organized on the Out-let table for bundling. This seamless integration within the Light Gauge Steel Frame Roll Forming Machine guarantees dimensional accuracy, minimizes material waste, and delivers the consistent, high-volume output necessary for large-scale projects.

A cornerstone of this system is its exceptional customizability and certified global compliance. We understand that building codes and architectural designs vary worldwide. Therefore, the Light Gauge Steel Frame Roll Forming Machine is built to be tailored to your needs. Key parameters—including material entry width, steel thickness (gauge) capacity, operational voltage, and the touch-screen HMI language—are fully customizable. This flexibility ensures perfect integration into your factory.

Crucially, the machine is CE certified, providing undeniable assurance of its safety, quality, and adherence to stringent European health and environmental directives. This certification is a powerful tool for building client trust and facilitating seamless entry into regulated international markets.

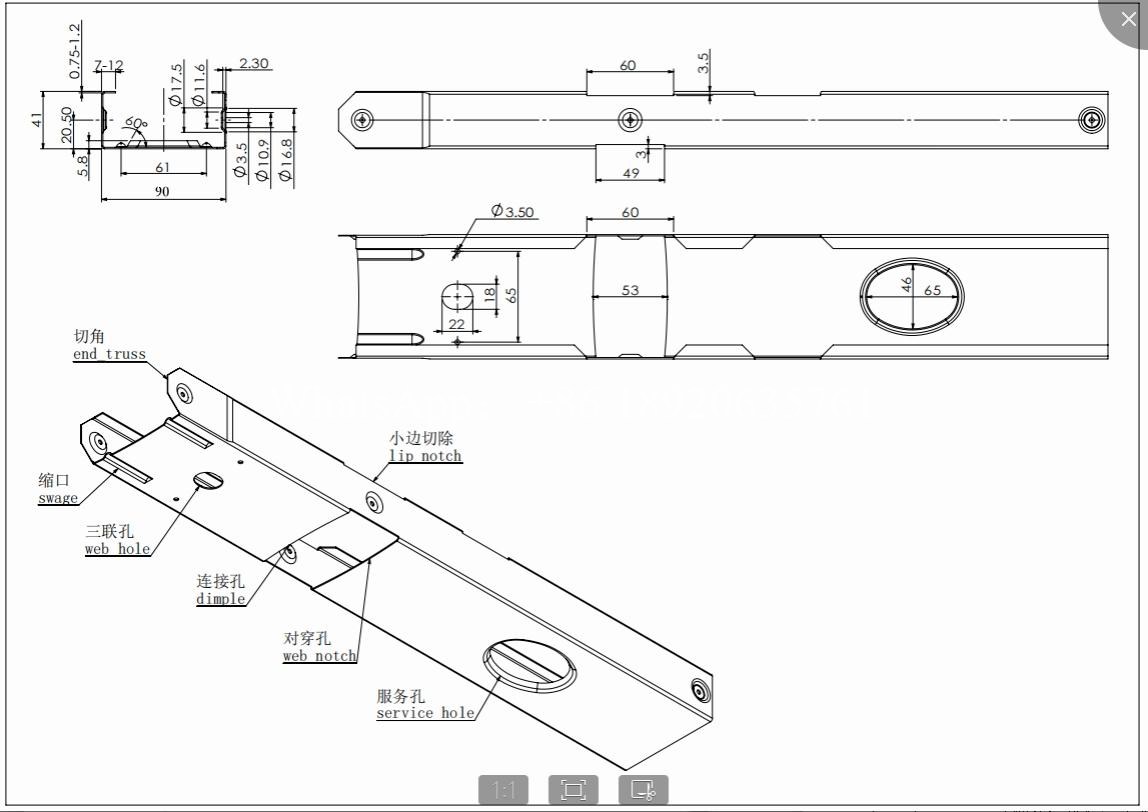

| Product Name | Light Gauge Steel Frame Roll Forming Machine |

| Formed Material | Steel strip |

|

Profile Width(web)

|

90mm |

|

Profile Height(flange)

|

41mm |

|

Lips

|

7-12mm |

| Machine size | (length)5.5m x (width)1.25m x (height)1.65m |

| Machine weight | About 3.8T |

| Material Thickness | 0.75-1.20mm(22 gauge to 18 gauge),G550 Galvanized Strip Steel |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 15 rows(As your requirement) |

|

Roller Material

|

GCr15, heat treat to HRC58-60 after CNC processing, and then finish turning, polishing and electroplatin |

|

Diameter of main shaft

|

ø60mm |

|

Material of main shaft

|

40Cr, after CNC processing, hrc28-32 is quenched and tempered, and then polished and electroplated |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutting material | Cr12 Cr12MoV Cr12 (3 blades for cutting to specific specifications) |

| Servo motor | Servo motor (7.5KW) + precision planetary gear reducer (Taiwan APEX)(7.5KW) + precision planetary gear reducer (Taiwan APEX) |

| Hydraulic station | 7.5 kw |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase(customizable) |

| Forming speed |

High speed 48m/min, the actual production speed you can communicate separately) |

| Transmission method | Gear transmission |

| Cutting tolerance | +-1.0 mm |

In essence, the Light Gauge Steel Frame Roll Forming Machine represents a strategic investment in the future of construction. It provides the dedicated capability to manufacture the essential frames for durable, energy-efficient, and rapidly built light steel structures. By implementing this advanced Light Gauge Steel Frame Roll Forming Machine, you are not just acquiring equipment—you are deploying a precision manufacturing solution engineered for efficiency, adaptability, and long-term leadership in the modern building sector.

28 years of professional R&D team

One-stop-solution for roll forming machine

Long-life stable running

High-precision finished products

High-quality raw materials

Brand electrical parts

About us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a Light Gauge Steel Frame Roll Forming Machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Light Gauge Steel Frame Roll Forming Machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.