WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

Featuring high automation;

Superior precision;

Excellent efficiency;

User-friendly operation.

WhatsApp: 0086 18920635761

E-mail: lisa@hx-machinery.com

In the realm of modern construction and industrial fabrication, consistency, strength, and efficiency are paramount. The U-channel profile, a fundamental component in building frameworks, support structures, shelving systems, and countless industrial applications, demands manufacturing precision to ensure structural integrity and assembly compatibility. To meet this critical need, we introduce our Professional U Channel Roll Forming Machine, a state-of-the-art equipment solution engineered for the high-volume production of superior-quality U-channel sections. This Professional U Channel Roll Forming Machine embodies a commitment to excellence, combining robust mechanical design with intelligent controls and certified safety standards. It is designed not merely as a machine, but as a complete, reliable production asset for fabricators seeking to enhance their capability and market competitiveness with precision-formed components.

The operational core of the Professional U Channel Roll Forming Machine is a streamlined, automated process optimized for accuracy and throughput.

The cycle begins with a precision decoiling system that introduces steel coil into the production line with controlled tension, ensuring a flawless and consistent feed—the essential foundation for dimensional stability.

The heart of the operation lies in the meticulously engineered roll forming station. Here, the flat steel strip is progressively guided through a series of hardened, computer-designed roll dies. Each set of rolls performs an incremental form, gradually and precisely shaping the metal into the defined U-channel geometry with exact leg heights, consistent flange widths, and perfect 90-degree angles.

Upon completion of the forming process, a high-speed, servo-controlled flying shear delivers a clean, burr-free cut at precisely programmed lengths.

This automated sequence within the Professional U Channel Roll Forming Machine guarantees exceptional product uniformity, maximizes material yield, and enables sustained production with minimal operator intervention.

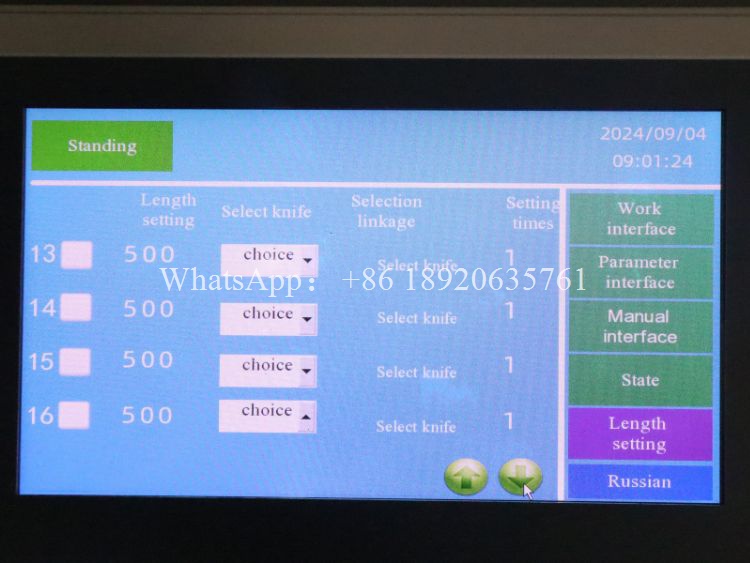

A standout advantage of our Professional U Channel Roll Forming Machine is its comprehensive customizability and user-focused engineering, which directly translates to operational flexibility. Recognizing the diverse requirements of global manufacturers, this equipment can be tailored to specific production environments. Key parameters, including the maximum incoming material width, the range of acceptable metal thickness (gauge), the main drive system voltage, and the language interface on the intuitive touch-screen, are all configurable. This adaptability ensures the Professional U Channel Roll Forming Machine integrates seamlessly into any workshop and can be quickly reconfigured for different project specifications. Furthermore, the machine’s design and construction adhere to the highest safety benchmarks, as validated by its CE certification. This mark is a crucial assurance of compliance with European Union directives for machinery safety, providing peace of mind and facilitating market access in regions with stringent regulatory frameworks.

| Product Name | Professional U Channel Roll Forming Machine |

| Formed Material | Steel strip |

| Machine size | 5900*900*1500mm |

| Machine weight | 2400kg |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12 rows(As your requirement) |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5KW |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase(customizable) |

| Forming speed | 40-50m/min(The speed depends on the shape of the tile and the thickness of the material) |

| Transmission method | Gear transmission |

| Cutting tolerance | +-1.0 mm |

To ensure our clients derive maximum value and uptime from their investment, we support the Professional U Channel Roll Forming Machine with an extensive remote assistance program. Our team of engineers provides real-time video guidance for installation, comprehensive operator training, proactive troubleshooting, and scheduled maintenance support. This digital partnership minimizes potential downtime and ensures the Professional U Channel Roll Forming Machine operates at peak efficiency throughout its service life.

Investing in our Professional U Channel Roll Forming Machine is a strategic decision to build manufacturing excellence in the structural components sector. This robust, versatile, and certified equipment empowers fabricators to reliably supply the market with high-tolerance U-channels that form the skeleton of modern infrastructure, from construction projects to industrial storage solutions. By implementing this sophisticated Professional U Channel Roll Forming Machine, you are not just purchasing a piece of industrial machinery—you are acquiring a precision manufacturing partner engineered for durability, flexibility, and long-term profitability.

28 years of professional R&D team

One-stop-solution for roll forming machine

Long-life stable running

High-precision finished products

High-quality raw materials

Brand electrical parts

About us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a Professional U Channel Roll Forming Machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Professional U Channel Roll Forming Machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.